3D-COAST

3-Dimensional Cultivation of Oysters Automated with Solar Tumbling

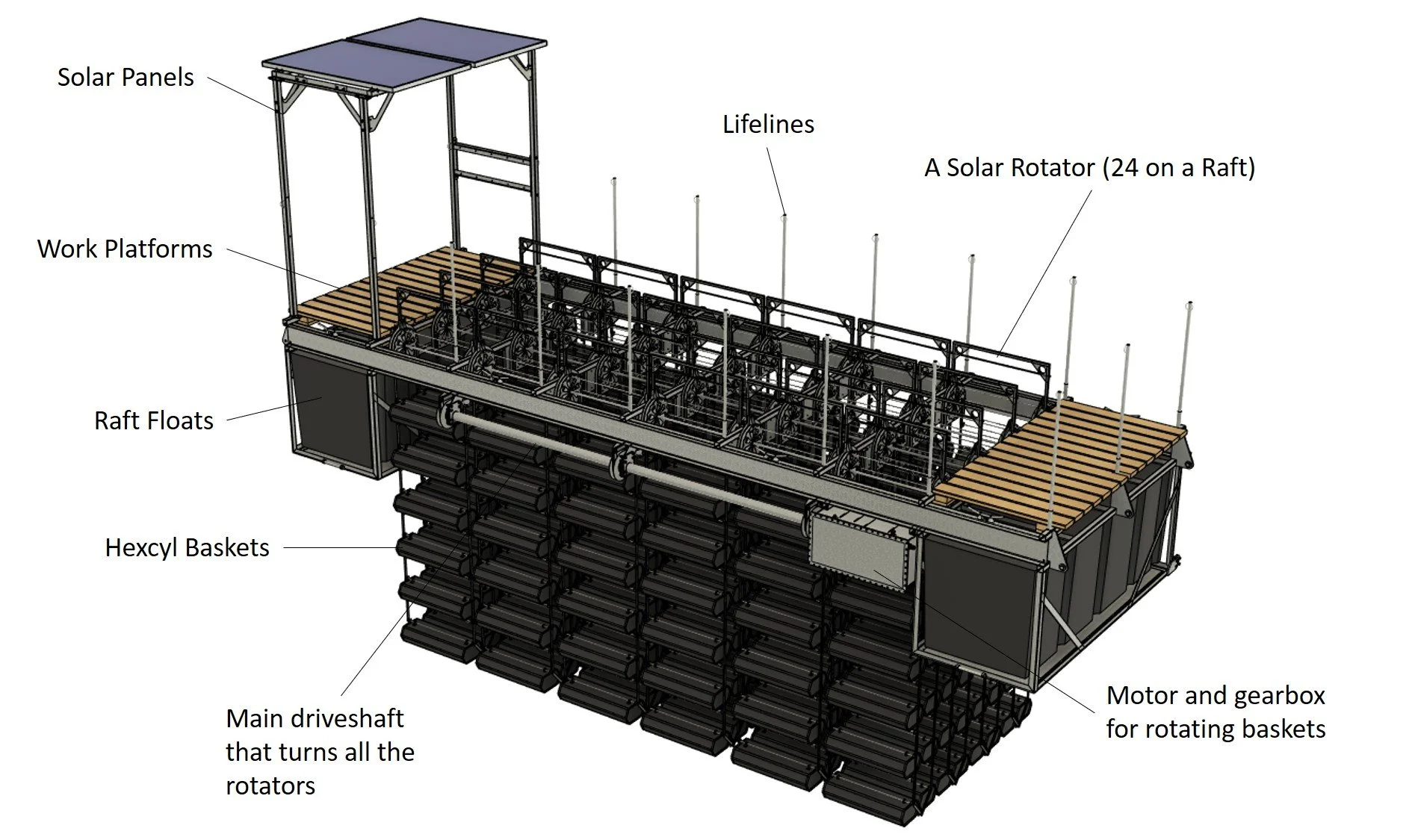

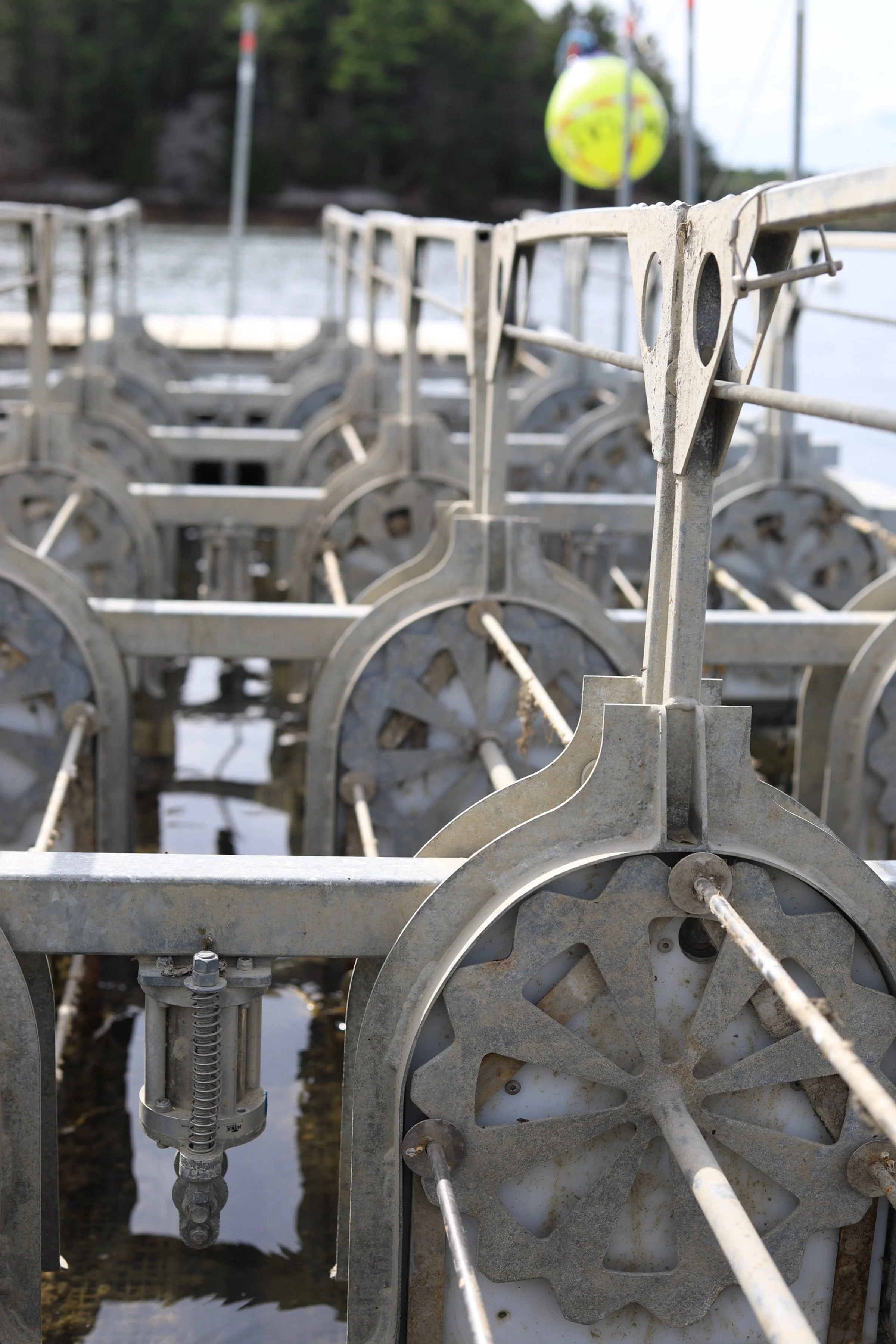

What makes this system especially unique is its gentle, solar-powered motion. The oyster baskets are slowly and continuously rotated up and down throughout the day, creating a natural tumbling effect. This motion helps oysters grow into strong, deep-cupped shapes that are easier to shuck and more consistent in size—qualities that are highly valued by chefs and seafood lovers alike.

As the baskets reach the top of their cycle, they are exposed to sun and air for a few hours each day. This dries and kills biofouling—like algae, barnacles, and other organisms that can clog the baskets, blocking water flow and depriving the oysters of food. Traditional farms often rely on manual scrubbing or pressure washing to clean cages, but this system eliminates that need.

Oyster farming is currently extremely manual, labor intensive, and strenuous. Much of this labor comes from cleaning oyster baskets and tumbling the oysters regularly. Reducing the time spent on these tasks would reduce injury, retain workers, and increase the number of oysters a farm could produce with their crew.

The entire system runs on solar power—just two panels are enough to keep one raft in constant, gentle motion. Each raft rotates all its baskets through a full cycle every six hours, ensuring that every oyster gets regular exposure to both tumbling and air drying. By combining renewable energy, efficient space use, and reduced manual labor, the 3D-COAST system offers a smart and effective way to farm oysters.

3D-COAST is an innovative, solar-powered oyster farming platform designed to grow oysters more efficiently and sustainably. Unlike traditional methods that rely on farming oysters at the water’s surface or on the seafloor, this system uses the full depth of the water column. Oyster baskets are suspended vertically, allowing more oysters to be grown in a smaller footprint while still maintaining healthy conditions.

A 48 hour time lapse of the 3D-COAST system

Photos by Jacqueline Clarke, Monique Boutin, and Luke Saindon.

Challenges in Oyster Farming — and How 3D-COAST Solves Them

1. Labor-Intensive & Injury-Prone

Oyster farming is physically demanding, especially cleaning and tumbling baskets. 3D-COAST automates both, improving efficiency, reducing injuries, and boosting profitability.

2. High Barrier to Entry

New farms often wait 5–10 years to turn a profit. 3D-COAST speeds up permitting and growth by using smaller farm sites and increasing margins—shortening the path to profitability.

3. Social Licensing Challenges

3D-COAST significantly reduces farm footprint, easing concerns over views and competition for ocean space with other harvesters.

4. Inconsistent Product Quality

Manual systems often lead to uneven quality. With continuous solar-powered motion, 3D-COAST produces consistently high-quality oysters—round, deep-cupped, and meaty.

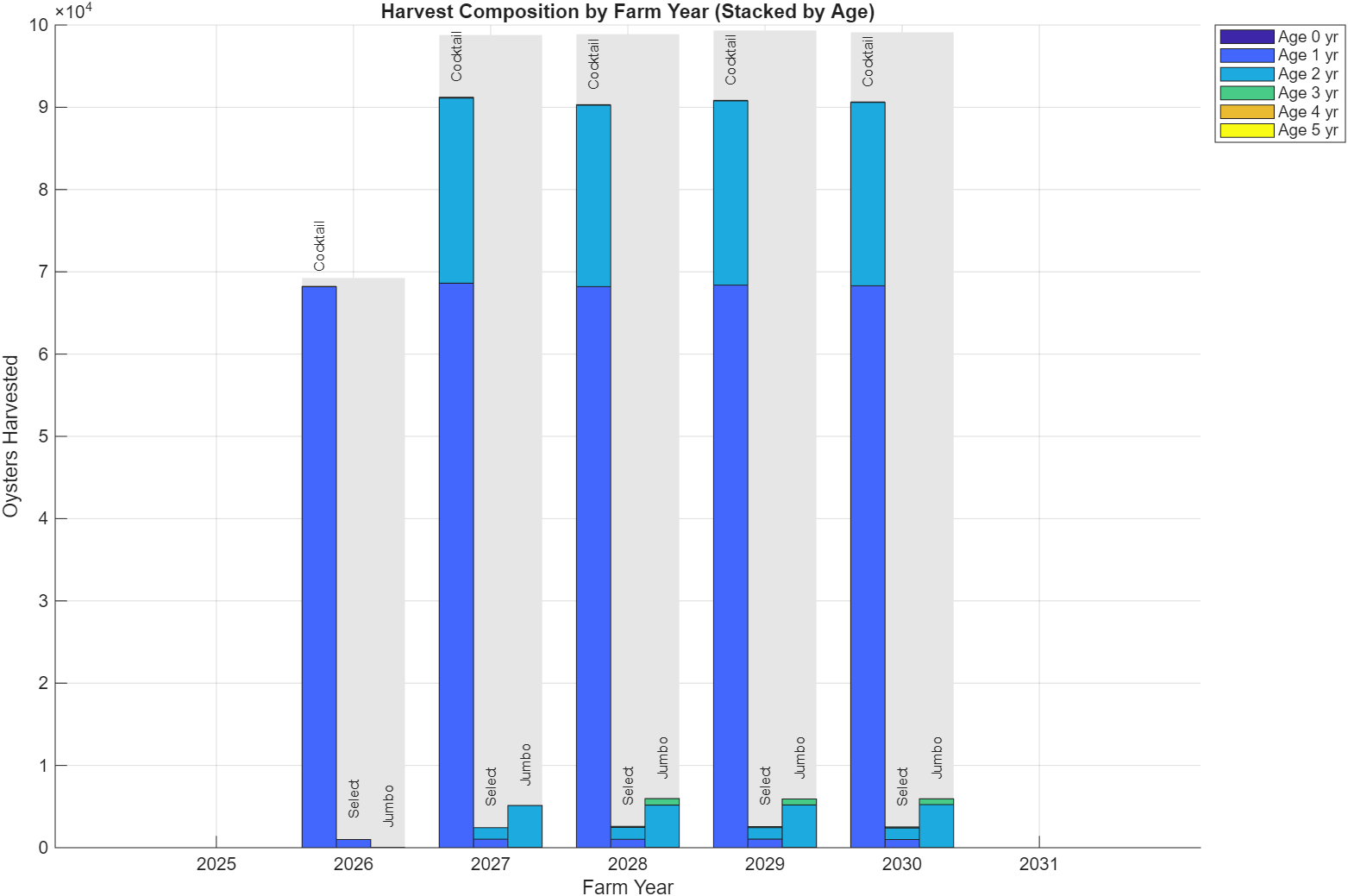

Production Modelling Software

Using data collected on the farm TWIYO has built a sophisticated production model that mimics actual farm dynamics to predict performance and resource utilization. Download the installer below to play around with the possibilities:

TWIYO Production Model Version 1.0 - Windows Only

This material is based upon work supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, through the Northeast Sustainable Agriculture Research and Education program under subaward number FNE25-131.

3D-COAST Acknowledgments

The 3D-COAST project has been an ongoing development effort and one that would not be possible without the continued support of many organizations and individuals. The first round of development was funded by Focus Maine and Maine Technology Institute (MTI). TWIYO has subsequently secured a SBIR (Small Business Innovation Research) Phase I grant with the generous support of the USDA. Follow on support has come from the Northeast Sustainable Agriculture Research and Education program (NE SARE) through the USDA as well as from the Island Institute which is helping bridge the development gap to a possible Phase II SBIR award. Generous technical assistance has come from the University of Maine cooperative extension, the Darling Marine Center, Maine Sea Grant, Nor’Easter Oyster Company, and the Maine Aquaculture Association.